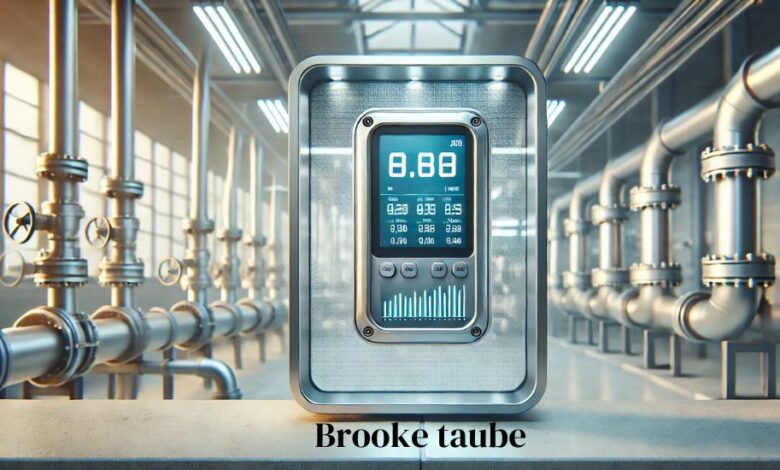

Understanding the Miratic Flow Meter The Display Device A Comprehensive Guide

In the realm of industrial measurement and fluid management, precision and reliability are paramount. The Miratic Flow Meter The Display Device emerges as a pivotal tool designed to meet these critical needs. This article delves deep into the functionalities, features, applications, and benefits of the Miratic Flow Meter The Display Device, providing a thorough understanding of its role in various industries.

What is the Miratic Flow Meter The Display Device?

The Miratic Flow Meter The Display Device is an advanced instrument engineered to accurately measure the flow rate of liquids and gases in diverse industrial settings. Unlike traditional flow meters, the Miratic Flow Meter integrates a sophisticated display unit that provides real-time data, enhancing the ability to monitor and manage fluid dynamics effectively. This device is essential for industries where precise flow measurement is crucial for operational efficiency, safety, and compliance with regulatory standards.

Key Features of the Miratic Flow Meter The Display Device

High Precision Measurement

One of the standout features of the Miratic Flow Meter The Display Device is its unparalleled precision. Equipped with state-of-the-art sensors and advanced technology, this device ensures that flow measurements are accurate even in challenging environments. Whether dealing with high-pressure systems or corrosive fluids, the Miratic Flow Meter maintains consistent performance, reducing the margin of error and enhancing data reliability.

Real-Time Data Display

The real-time data display is a fundamental component of the Miratic Flow Meter. This feature allows operators to monitor flow rates instantaneously, facilitating immediate adjustments to processes as needed. The digital interface presents data in a clear and concise manner, enabling quick decision-making and minimizing the risk of human error. This real-time monitoring is especially beneficial in applications where timing and precision are critical, such as chemical processing or water treatment.

Durability and Versatility

Designed to withstand the rigors of industrial environments, the Miratic Flow Meter The Display Device boasts a robust construction that resists corrosion, temperature fluctuations, and mechanical wear. This durability ensures long-term reliability and reduces the need for frequent maintenance or replacements. Additionally, the device’s versatility allows it to be used across a wide range of applications, from oil and gas pipelines to food and beverage production lines, making it a versatile solution for various industries.

User-Friendly Interface

Ease of use is another significant advantage of the Miratic Flow Meter The Display Device. The intuitive interface is designed to be accessible to both seasoned professionals and new users, requiring minimal training. Clear visual displays, straightforward navigation, and customizable settings make it easy for operators to interpret data and manage flow measurements effectively. This user-centric design enhances operational efficiency and reduces the likelihood of errors during data interpretation.

Applications of the Miratic Flow Meter The Display Device

Water and Wastewater Treatment

In the water and wastewater treatment industry, precise flow measurement is essential for maintaining regulatory compliance and ensuring the efficiency of treatment processes. The Miratic Flow Meter The Display Device accurately monitors the flow of water and chemicals, enabling facilities to optimize their operations, reduce waste, and ensure the delivery of clean water. Its durability and resistance to corrosion make it an ideal choice for harsh treatment environments.

Pharmaceutical and Chemical Processing

Pharmaceutical and chemical industries demand exact flow measurements to maintain product quality and safety. The Miratic Flow Meter The Display Device provides the high level of accuracy required for these applications, ensuring that ingredients and chemicals are measured precisely during production. This accuracy not only improves batch consistency but also enhances quality control processes, reducing the risk of contamination and ensuring compliance with stringent industry standards.

Food and Beverage Production

Consistency and quality are paramount in the food and beverage sector. The Miratic Flow Meter The Display Device plays a crucial role in monitoring the flow of liquid ingredients such as syrups, oils, and water. By ensuring accurate measurements, the device helps maintain product consistency, reduce waste, and enhance overall production efficiency. Its hygienic design and ease of cleaning make it particularly suited for environments where cleanliness and sanitation are critical.

Oil and Gas Industry

The oil and gas industry operates in some of the most demanding conditions, requiring equipment that can withstand extreme pressures and temperatures. The Miratic Flow Meter The Display Device excels in these environments, providing reliable flow measurements in pipelines and processing facilities. Its ability to handle high-pressure systems and temperature fluctuations ensures the safe and efficient transport of oil and gas, minimizing the risk of leaks and operational disruptions.

Comparison with Traditional Flow Measurement Methods

Traditional flow measurement methods, such as mechanical devices like rotameters and gear meters, often suffer from limitations in accuracy and reliability. These devices can be prone to wear and tear, leading to inconsistent measurements and the need for frequent maintenance. Additionally, manual reading of these devices increases the risk of human error, further compromising measurement accuracy.

In contrast, the Miratic Flow Meter The Display Device leverages advanced technology to deliver superior precision and reliability. The digital display eliminates the ambiguity associated with manual readings, providing clear and accurate flow data at a glance. Furthermore, the device’s ability to integrate with industrial control systems allows for automated monitoring and data logging, enhancing overall operational efficiency and reducing the likelihood of errors.

Installation and Integration

Easy Installation Process

The Miratic Flow Meter The Display Device is designed for straightforward installation, allowing for quick integration into existing systems without extensive modifications. Its compact and streamlined design ensures that it can be easily mounted in various settings, whether in new installations or as upgrades to existing setups. Clear installation guidelines and compatibility with different piping systems further simplify the process, minimizing downtime and ensuring a smooth transition.

Seamless Integration with Control Systems

Integration with industrial control systems is a key feature of the Miratic Flow Meter The Display Device. The device supports various communication protocols, enabling seamless connectivity with automation tools and monitoring systems. This integration allows for centralized data management, real-time monitoring, and automated adjustments based on flow measurements. By connecting the flow meter to other control systems, businesses can achieve a more cohesive and efficient operational workflow.

Maintenance and Calibration

Regular Maintenance Practices

To ensure the longevity and accuracy of the Miratic Flow Meter The Display Device, regular maintenance is essential. This includes routine cleaning of sensors to prevent dirt and debris buildup, which can affect measurement accuracy. Inspecting and maintaining the device’s components helps in identifying potential issues early, reducing the risk of unexpected downtime and ensuring continuous reliable performance.

Calibration for Continued Accuracy

Calibration is a critical aspect of maintaining the device’s precision over time. The Miratic Flow Meter The Display Device is equipped with built-in calibration features that allow for easy and accurate adjustments. Regular calibration ensures that the device remains aligned with industry standards and continues to provide accurate flow measurements. By adhering to a strict calibration schedule, businesses can maintain the integrity of their flow data and uphold high-quality standards in their operations.

Benefits of Using the Miratic Flow Meter The Display Device

Enhanced Measurement Accuracy

The primary benefit of the Miratic Flow Meter The Display Device is its ability to deliver highly accurate flow measurements. This precision is crucial for industries where exact fluid dynamics are essential for product quality, safety, and regulatory compliance. By providing reliable data, the device helps businesses make informed decisions, optimize processes, and maintain consistent quality standards.

Improved Operational Efficiency

Real-time data display and seamless integration with control systems significantly enhance operational efficiency. Operators can monitor flow rates continuously, allowing for immediate adjustments and reducing the need for manual interventions. This automation streamlines processes, minimizes downtime, and ensures that operations run smoothly and efficiently.

Cost Savings and Waste Reduction

Accurate flow measurement directly translates to cost savings by reducing waste and optimizing resource management. In industries such as pharmaceuticals and food production, precise measurements prevent overuse of ingredients and minimize product loss. Additionally, by identifying and addressing flow inconsistencies promptly, businesses can avoid costly operational disruptions and maintain steady production rates.

Increased Reliability and Longevity

The durable construction of the Miratic Flow Meter The Display Deviceensures long-term reliability, even in harsh industrial environments. Its resistance to corrosion, pressure, and temperature fluctuations reduces the need for frequent maintenance and replacements, further contributing to cost savings and uninterrupted operations.

User-Friendly Operation

The intuitive interface and easy-to-navigate display make the device accessible to a wide range of users, from experienced technicians to new operators. This user-friendly design reduces the learning curve, enhances productivity, and minimizes the likelihood of errors during data interpretation and process management.

Case Studies: Real-World Applications of the Miratic Flow Meter The Display Device

Enhancing Water Treatment Efficiency

A municipal water treatment facility implemented the Miratic Flow Meter The Display Device to monitor and manage water flow through their treatment processes. The real-time data display allowed operators to detect flow irregularities promptly, enabling swift adjustments to maintain optimal treatment conditions. As a result, the facility achieved a 20% increase in operational efficiency and a significant reduction in water waste, ensuring compliance with environmental regulations.

Streamlining Pharmaceutical Production

A pharmaceutical company integrated the Miratic Flow Meter The Display Device into their liquid formulation processes. The device’s high precision and real-time monitoring capabilities ensured consistent measurement of active ingredients, enhancing batch consistency and product quality. This implementation led to improved quality control, reduced production errors, and increased overall productivity, reinforcing the company’s reputation for reliability and excellence.

Optimizing Oil Pipeline Management

An oil and gas company utilized the Miratic Flow Meter The Display Device to monitor flow rates in their extensive pipeline network. The device’s durability and accuracy were critical in managing high-pressure flows and ensuring the safe transport of oil. Real-time data enabled the company to detect and address flow anomalies swiftly, preventing potential leaks and operational disruptions. This proactive approach enhanced pipeline safety and operational reliability, safeguarding both the environment and the company’s assets.

Future Innovations and Developments

The Miratic Flow Meter The Display Device continues to evolve with advancements in technology. Future developments are expected to incorporate enhanced connectivity features, such as wireless data transmission and integration with Internet of Things (IoT) platforms. These innovations will further streamline data management, enabling more sophisticated analytics and predictive maintenance. Additionally, improvements in sensor technology will likely enhance measurement accuracy and expand the device’s applicability to even more challenging environments and applications.

Conclusion

The Miratic Flow Meter The Display Device stands out as a vital tool for industries that rely on precise and reliable flow measurements. Its advanced features, including high precision, real-time data display, durability, and user-friendly interface, make it an indispensable asset for optimizing operations, ensuring quality, and maintaining regulatory compliance. Whether in water treatment, pharmaceuticals, food production, or oil and gas, the Miratic Flow Meter The Display Device delivers the accuracy and reliability that modern industries demand. Investing in this device not only enhances operational efficiency but also contributes to significant cost savings and improved resource management, making it a smart choice for businesses aiming for excellence in fluid management.